MSS (Digitization of data capture)

Microtunneling Support System (MSS)

MSS allows centralised, automated storage and management of all data generated during tunnelling (e.g. from the TBM, survey, pipe monitoring, guidance, annular gap lubrication, etc.) and makes this data available quickly and easily in both graphical and numerical form. This allows the tunnelling contractor and the other project participants to carry out versatile and case-related evaluations and analyses of the ongoing tunneling process. MSS has been specifically developed for the needs of pipe jacking and microtunnelling (as well as related processes such as DirectPipe ®) and is characterised by the following main features:

- Simple and convenient data management.

- Open system architecture for all available data.

- Simple and intuitive application.

- Fast and simple analysis functions.

- Transparency for all persons involved in the project.

- BIM compatibility.

- Simple and convenient work reporting for tunnelling companies.

- Monitoring of jacking pipes and pressure transfer rings.

JCPipe – Quality assurance in pipe jacking / microtunnelling

all current standards used in pipe jacking can be taken into account, e.g. DWA-A 125 and 161, EN 1916, SIA 195, CPAA, PJA, etc.

Jack Director®

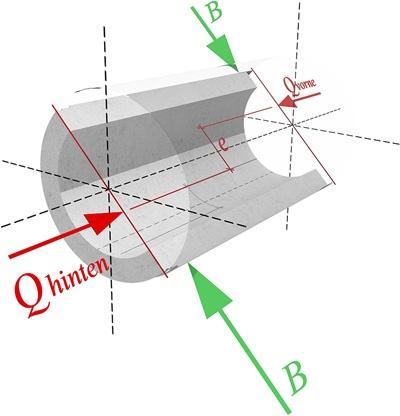

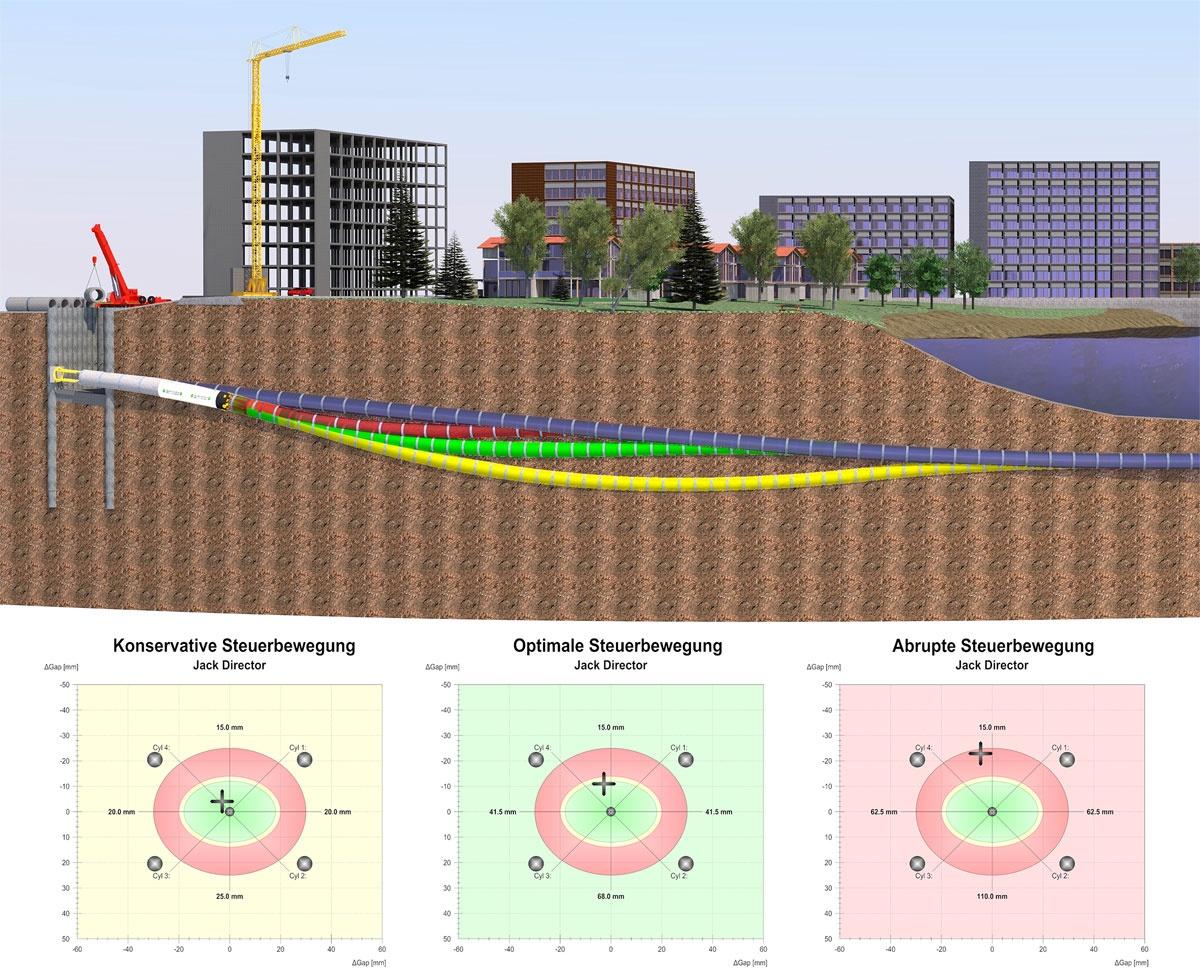

Large angular movements in the pipeline must be avoided, because they result in reductions of the admissible jacking forces. But how should the TBM operator control the drilling equipment so that excessive articulation changes and thus reduced admissible jacking forces can be avoided? The Jack Director ® software module provides valuable support here: Using the measured movements and positions of the steering cylinders of the TBM, the Jack Director ® software evaluates the steering movements of the TBM and compares them with the effective measured joint articulation angles on the subsequent jacking pipes and thus the admissible jacking forces.

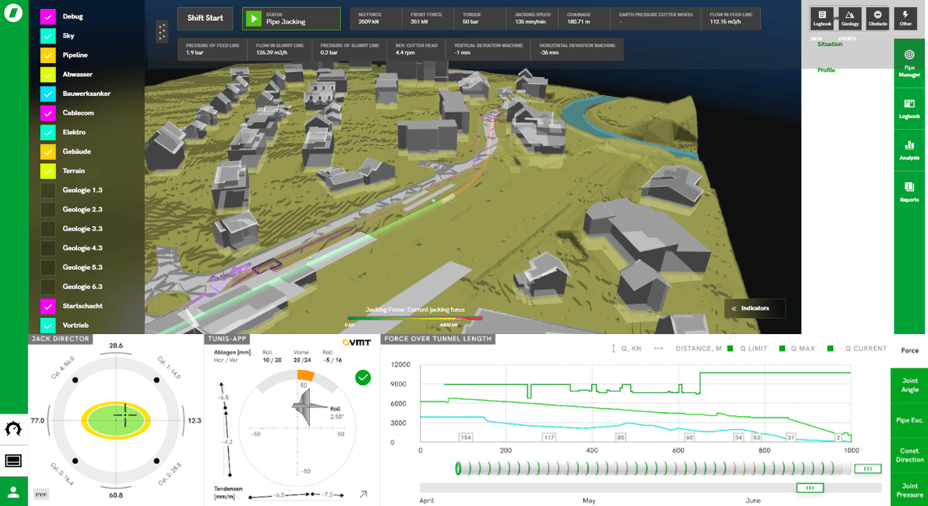

MSSTUnIS

The MSSTUnIS option provides the following advantages to the user:

- Optimum, intuitively understandable display at a glance for TBM operator.

- Synergies and cost-saving on the hardware side.

- Time saving for assembly and commissioning.

- Full integration of the guidance system into the data management.

- Optimum jobsite support.

Jack Director®

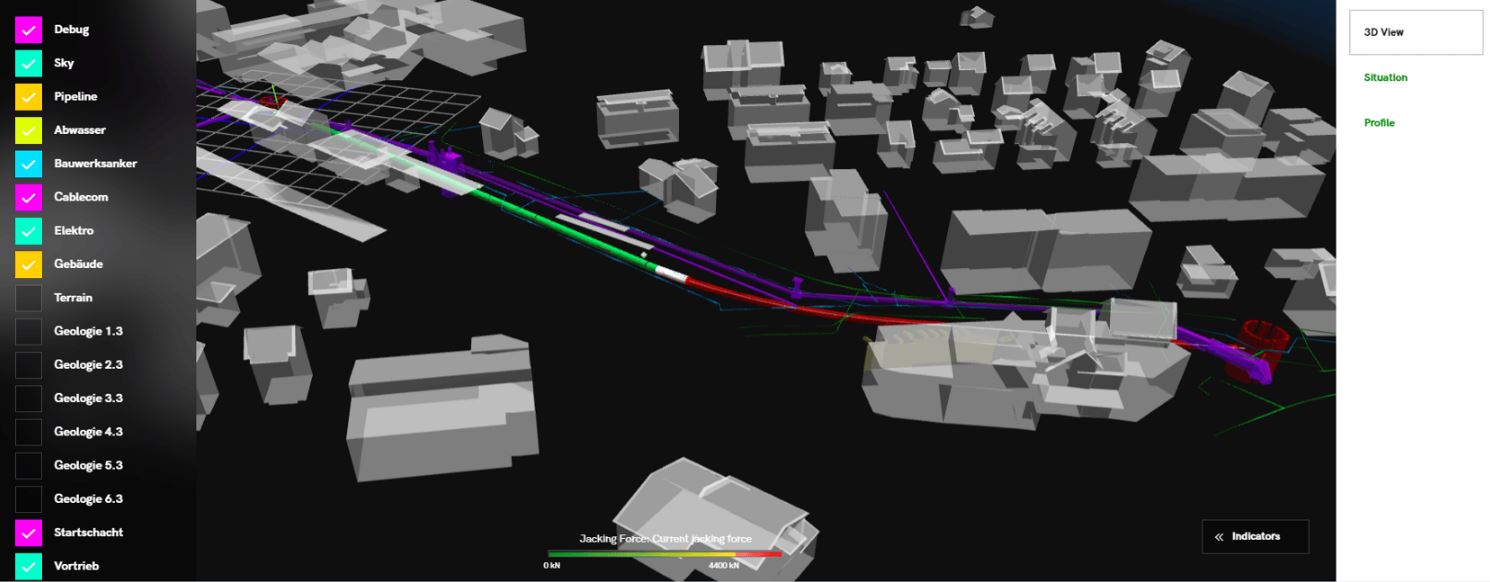

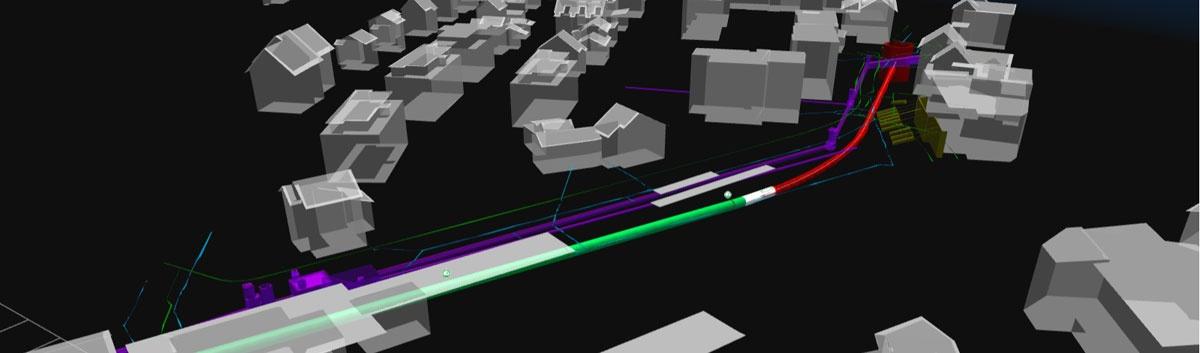

The Service Package 3D / BIM includes a three-dimensional display of the surroundings of the tunnel to be performed. The 3D model must be provided on site / by the tunnelling contractor, alternatively it can be generated by the CAD designers of Jackcontrol AG for an additional charge. The Service Package 3D / BIM also enables the recording and storage of all documents relating to the jacking pipes in electronic form (Arrow-right BIM attributes; e.g. pipe structural analysis, pipe plans, QC / QA documents, delivery notes, photos, etc.). These documents can be transferred to the

client after completion of the jacking process.

JCPipe – Quality assurance in pipe jacking / microtunnelling

all current standards used in pipe jacking can be taken into account, e.g. DWA-A 125 and 161, EN 1916, SIA 195, CPAA, PJA, etc.